Author Archives: Pack Form

RSC and HSC Cases

Equipment’s Description

The case erector CaseFORM GF / GH is the result of PackFORM’s 22 years experience on case erecting Regular Slotted Containers or Half Slotted Containers (RSC or HSC)..

Its project was developed along 2 years of studies, tests and proofs, which lead to the design of the world’s highest efficiency and performance case erector, outcome of PackFORM’s expertise on automation processes with cardboard cases.

Operation

The case erector is loaded with cardboard case bundles, erects and seals their bottom by applying adhesive tape or hot-melt, making the case ready to receiving products.

Watch the vídeos

Is your company still erecting cases manually? Contact us about the GF Case Erector!

Drop Packer

Descrição do Equipamento

The Drop Packer DropFORM EVG is destined to automatic product packing by drop (drop-packing or vertical case packing). Works with bottles of several shapes, like cylinders, oval, rectangular, on a variety of packing patterns.

This equipment presents efficiency ratio of 99%, bearing high line speeds. The case packer’s project is designed to maximum reduction of resetting, change over and maintenance times. All this, in order to providing the highest efficiency to the line.

Operation

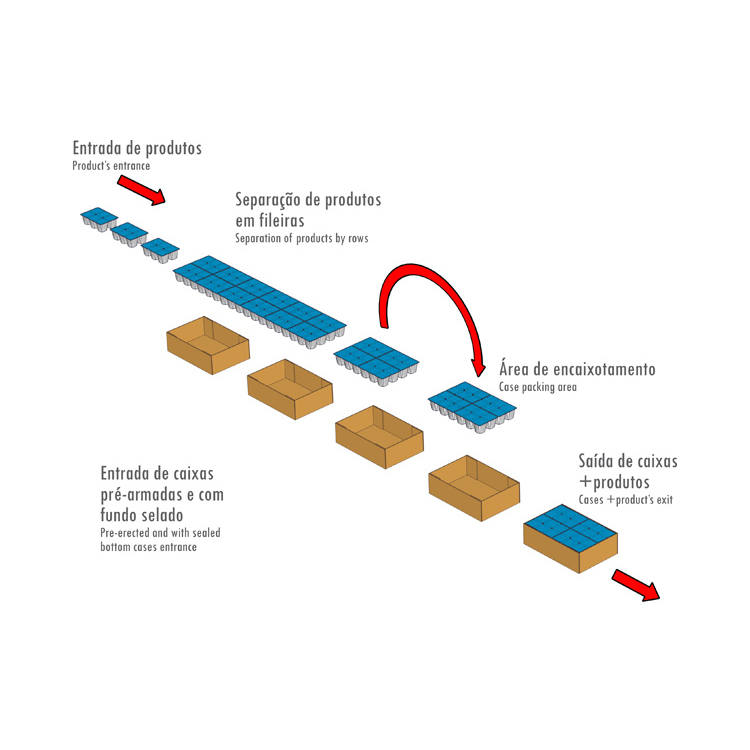

The Drop Packer gets the pre-erected cases and products from the filling line, splits the products on rows (according to the packing pattern) and places products in the transportation containers by drop.

Watch the vídeos

What to know more about automatic case packers? Contact us!

Tray, Lid and Bottom or Plateau Cases

Equipment’s Description

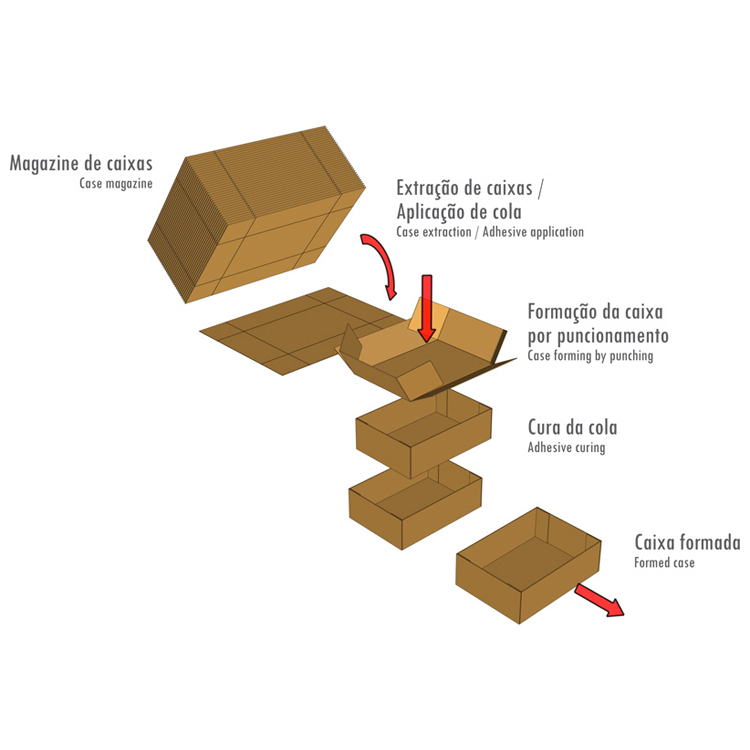

The Case Former TrayFORM TFV is an innovative equipment to forming corrugated trays – telescope, lid and bottom,reinforced, plateau, or fruit cases types. It is a consequence of a 18 month study, tests and proofs which resulted on the manufacturing of a high performance equipment, with speed and efficiency that make it reference both on national and international markets. Contact us about the best option to corrugated case forming for your company.

Operation

The case bundles are placed at the magazine, where each case is extracted individually and moved horizontally to the punching position, receiving hot-melt adhesive application. The case is punched vertically – top-bottom, being shaped at the die, where the flaps are folded and glued. The adhesive healing happens inside of the die, and when the tray leaves the machine, is ready to receive products.

Watch the vídeos

Longitudinal Pick and Place

Descrição do Equipamento

The Pick and Place Case Packer PlaceFORM EPP, does the automatic packaging of rigid containers the most varied formats, like bottles, jars, cans, trays, carton shells and packages, sachets and pillow bags.

The product’s handling is done through the pick’n’place (or pick-an-place) arm, equipped with suction cups or claws, according to the package shape. Its arm does a longitudinal movement for case packing, providing high speed to the machine.

Want to know if the pick and place case packer fits your company’s line of production? Contact us!!

Operation

Pick and Place Case Packer receives pre-erected cases and products from the filling line, splits the products on rows (according to the packing pattern) and softly places products in the transportation containers with the pick and place system.

Watch the vídeos

ELD SideFORM

PackFORM presented releases in End-of-Line Engineering at FCE 2013

- PackFORM stall at FCE Pharma 2013

The PackFORM Packaging Systems, a developer of solutions in Engineering Final Line for the pharmaceutical, cosmetic, chemical, cleaning, personal hygiene, food and beverage, presented novelties in the 18th FCE Pharma and Cosmetique, held from 14-May 16, at the Transamerica Expo Center, Sao Paulo, SP.

The company designs, manufactures and installs complete lines of process automation end line, in order to bring the customer in its solutions, benefits such as increased efficiency, speed and productivity, paying attention to the issues of security and convenience for operation and maintenance, meeting regulatory compliance sectors.

Discover the best equipment Engineering Final Line for its production.